Types of brake pads

During replacement of the worn spark plugs it is necessary:

1. Not to allow the dirtying around the spark plug hole enter the combustion chamber.

2. The spark plugs installation should be made with tightening torque, which is carefully chosen.

By too high tightening torque the spark plug could be damaged. The small tightening torque is the reason of bad compression and heat sink.

There is auxiliary installation tool for spark plugs screwing into, but manually installation is also possible. The thread lubricating is forbidden.

Depending on the spark plug type it is necessary to operate in a following way;

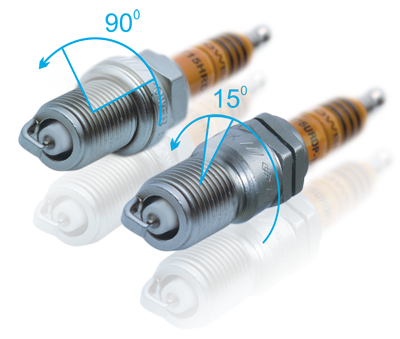

The spark plug with sealing washer is screwing into with help of fingers. Then it is tighten by spark-plug wrench on 90 degree (quarter of turn).

The spark plug without sealing washer with thread diameter 14 mm and 18 mm demands especially careful treatment in order to avoid over tighten. If during spark plug tightening there was applied too big torque it could cause blocking effect between conic surfaces of the spark plug and seat of the block head. The blocking effect will make spark plug replacement hard or impossible. Please screw the spark plug into with fingers up to the stop, afterwards tight with help of spark-plug wrench on 15 degree (1/16 of turn).

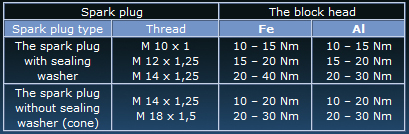

The tightening strain should not exceed value pointed out in below table.

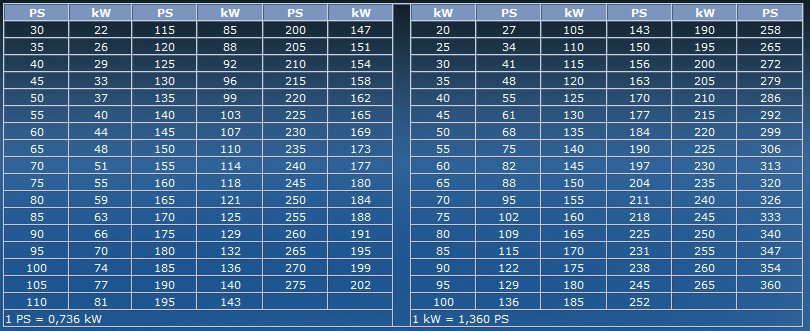

Table PS <--> kW

Menu

Spark plugs types Spark plugs marking Specifications Selection and exploitation...Proper spark plugs installation

Possible reasonsof faultinesses BACK(C) 2016 | HEXEN Automotive Systems